Our Expertise

Integrated Value

We know that balancing design quality with construction cost can be a challenge. That’s why we pride ourselves on being dedicated team players who speak your language—so together, we can achieve your goals. We listen carefully to the needs of our clients and end-users and consider the life of the structure so we can provide the most value possible.

We’re hyper-focused on providing good intelligence early and consistently in the design process to inform planning and budgeting. We’re sensitive to the fact that high construction costs and risk of escalation is a significant obstacle for projects, so we’re flexible and nimble throughout the project lifespan. As trusted partners, we work hand-in-hand with the design and construction team to carefully plan cost impacts and communicate clearly to avoid surprises.

Collaborative thought partners

We operate best as thought partners, with early, deep, and frequent collaboration. By integrating cost and constructability feedback early in our process, we’re able to find the right solution that can be delivered on time and within budget. Embodying the mindset of the architect, owner, developer, or contractor allows us to be responsive to the collective goals. Our technical skill, experience, ingenuity, and collaborative approach results in savings, expedited schedules, and improved performance.

The UC Berkeley David Blackwell Residence Hall project used a Public-Private Partnership (P3) model, which predetermined the parameters of the project, including key financial terms, in the development agreement before the design team was fully formed—so the design team is motivated to find the leanest possible design that meets the economic constraints of the project. In this framework, performance-based earthquake engineering (PBEE) offered real advantages in contrast to the prescriptive design approach. While PBEE is used as a means to demonstrate a high-performance objective in seismic performance, in this context, it was used to undergird a lean design that is integrated with the architecture and establishes reliable collapse prevention and protection of occupants.

Exploring the unexpected

As an active participant in the design process, we use dynamic problem solving and a nimble approach to question assumptions, provide valuable input, and explore solutions to design challenges, positively contributing to your project’s success. We use analytical modeling and exploration at the early stage of design to test ideas and unlock unexpected possibilities.

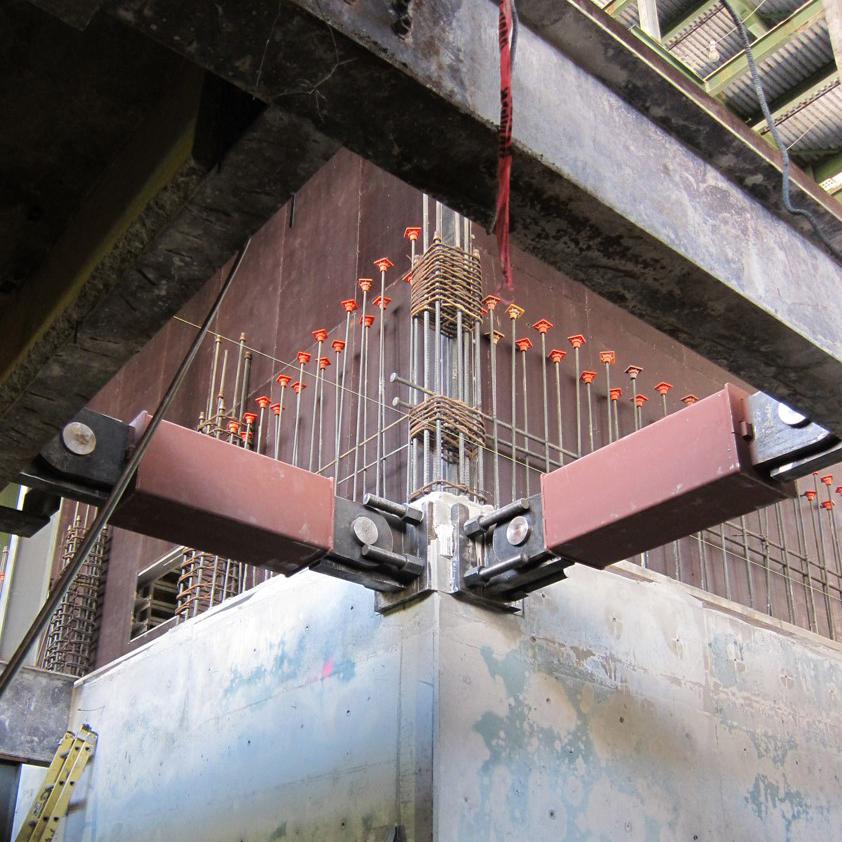

The ambitious gut renovation, seismic retrofit, and expansion of 680 Folsom Offices first began in 2007, was put on hold in 2008, and went through a value-engineering redesign in 2010. Our innovative structural solution lowered construction costs by $4 million and reduced the 100-week construction schedule by 10 weeks, while protecting the newly renovated building with an unconventional and elegant design that harnessed the strength of the existing steel frame. The team’s design relied on performance-based design principles, using nonlinear response history analysis to meet code requirements. The results of the analysis also allowed for a significant reduction in earthquake insurance premiums, decreasing lifespan building costs for the owner.

Data-driven analyses for value-based decisions

By leveraging our deep understanding of structural behavior and our suite of sophisticated custom-built analytical tools, we’re able to achieve solutions that otherwise might seem out of reach. By optimizing designs that reduce material use and shorten the construction schedule, our tools and data-driven process often result in less costly designs, bringing added value to your project. Learn more about advanced analytics.

Our design solutions for the SFPUC Headquarters cost-efficiently delivered immediate-reoccupancy performance; increased constructability; shortened construction time; and saved the project almost $30 million in direct, indirect, and downstream costs. We utilized a recent innovation from our team—a hybrid lateral system involving vertically post-tensioned concrete cores, adapted from bridge engineering, and designed to return a structure to plumb after a significant earthquake. In redesigning the SFPUC headquarters in concrete, Tipping implemented the latest iteration in a series of “self-centering” walls, meeting the performance mandate and budget. The design approach also reduced the depth of floor assemblies and allowed for an additional floor of program area. Additionally, the project made a 40% net reduction in carbon output through the use of green concrete mixes.

Seamless integration of structure and architecture

The integration of the structure into the architectural program is key to achieving necessary efficiencies in cost and function. We emphasize early collaboration with all major disciplines to identify and coordinate key elements of architectural design and mechanical systems with the structure, working closely with design teams to develop a structure that allows for the close integration of varied program and circulation elements. This collaboration provides the framework for an efficient and robust structural design that works with—not against—other critical building systems to enhance space planning and improve function within budget.

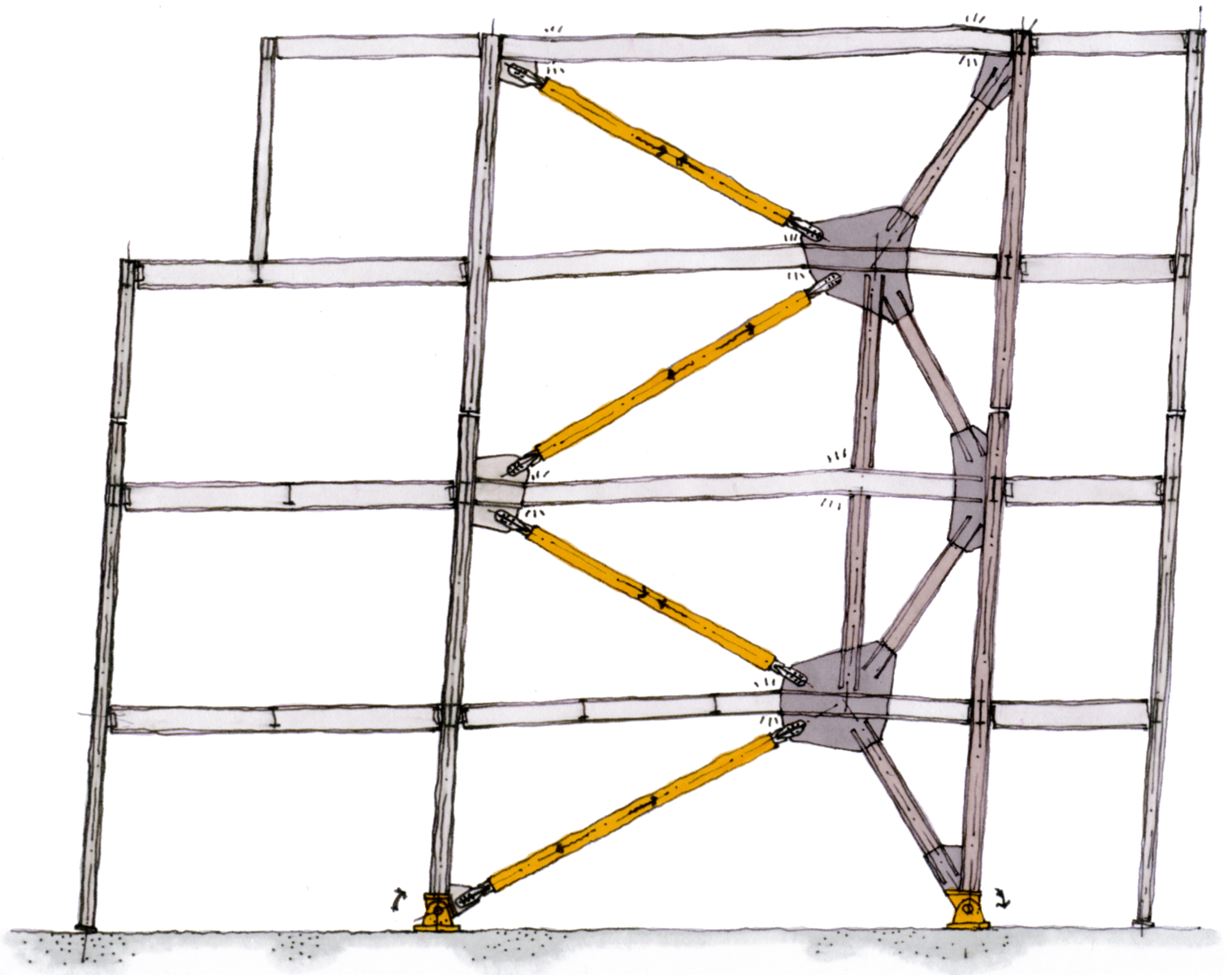

A steel BRB mast frame system at 740 Heinz provided superior efficiency over a conventional code-designed braced frame, allowing the number of required BRB frames to be cut from seven to four, and the total BRB frame elements reduced from 56 to 16. By eliminating bracing within the program areas, the innovative approach also allowed more flexibility for space-planning and accommodating multiple tenants, while also resulting in a construction cost savings of $360,000 for the project.

Featured Projects