Our Expertise

Sustainable Integration

Sustainability guides our approach to every structural design and is an essential part of every solution. From the outset of a project, our team collaborates and innovates with other disciplines to create sustainable solutions that are efficient, low cost, and seek to minimize the environmental impacts of construction.

For forty years, research, development, and continual creative exploration have been at the core of our sustainability practice. This ongoing commitment to sustainability has allowed us to pioneer green-building solutions that aim to reduce the long- and short-term impacts of building construction on the environment.

Tipping + SE2050

As part of our effort to create a more sustainable future, we joined the SE 2050 Program in 2021, formally committing to substantial reductions of embodied carbon in the structural systems we design. As part of this movement, we aspire to amplify our advocacy efforts including data and knowledge sharing to reduce the short- and long-term impacts of building construction on the environment.

Read our Embodied Carbon Action Plan.

A holistic approach to sustainability

We design to reduce the carbon footprint of every structure in multiple ways. We select structural materials with reduced carbon outputs and environmental impact, design optimized structural systems that minimize material quantities, and integrate resilient seismic solutions that protect buildings from excessive damage, reducing the environmental impact of demolition, replacement, and repair. We facilitate the retrofit and adaptive reuse of existing structures to avoid carbon expenditures associated with new construction and demolition, integrating structural design with architectural, mechanical, and constructability priorities to maximize performance and efficiency. Most importantly, we design for longevity through durability and adaptability, so the structures we create can be a positive part of the communities they exist in for decades to come.

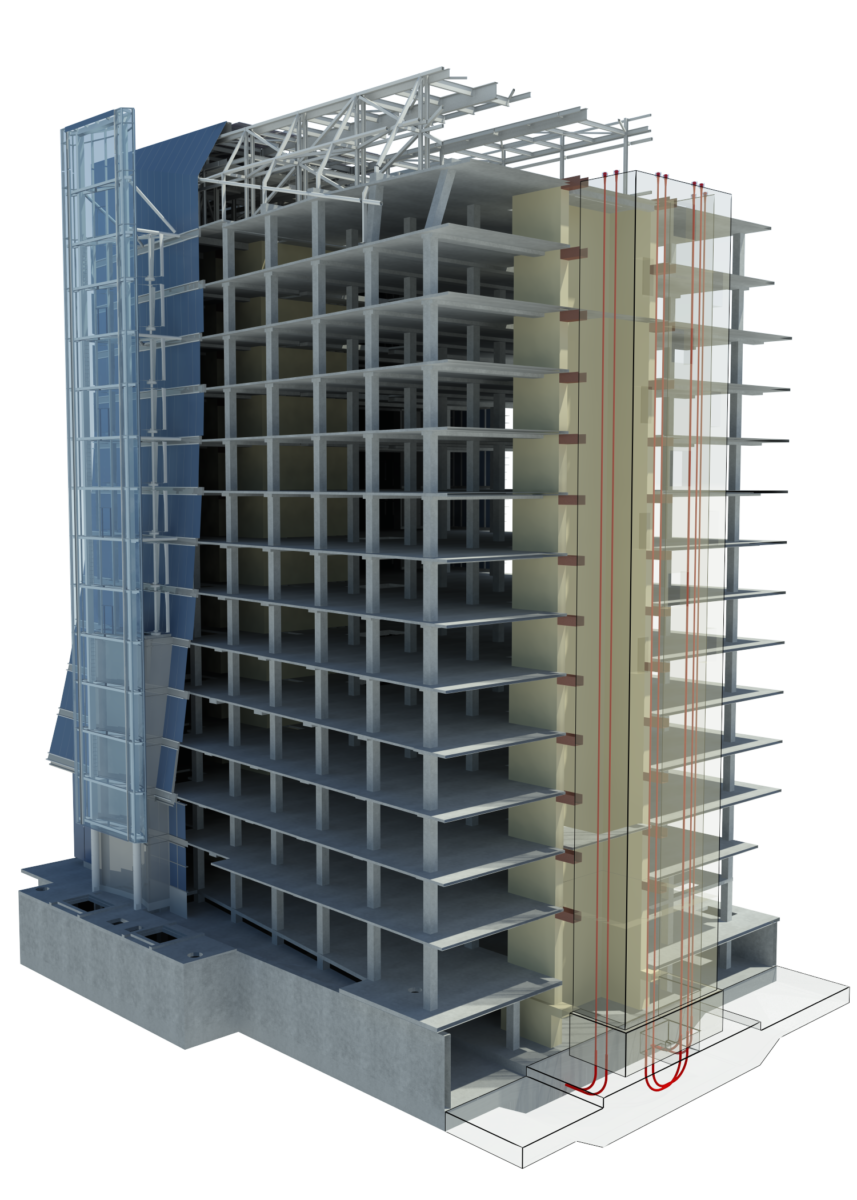

At the San Francisco Public Utilities Commission Headquarters, our approach to structural engineering resulted in cost and carbon reductions through several sustainable design solutions:

- By reducing floor-to-ceiling heights with our lateral system design, we were able to add a thirteenth story to the project and increase building density without increasing height.

- Reduced steel reinforcement—and materials emissions—by 50 percent through our optimized link-beam design.

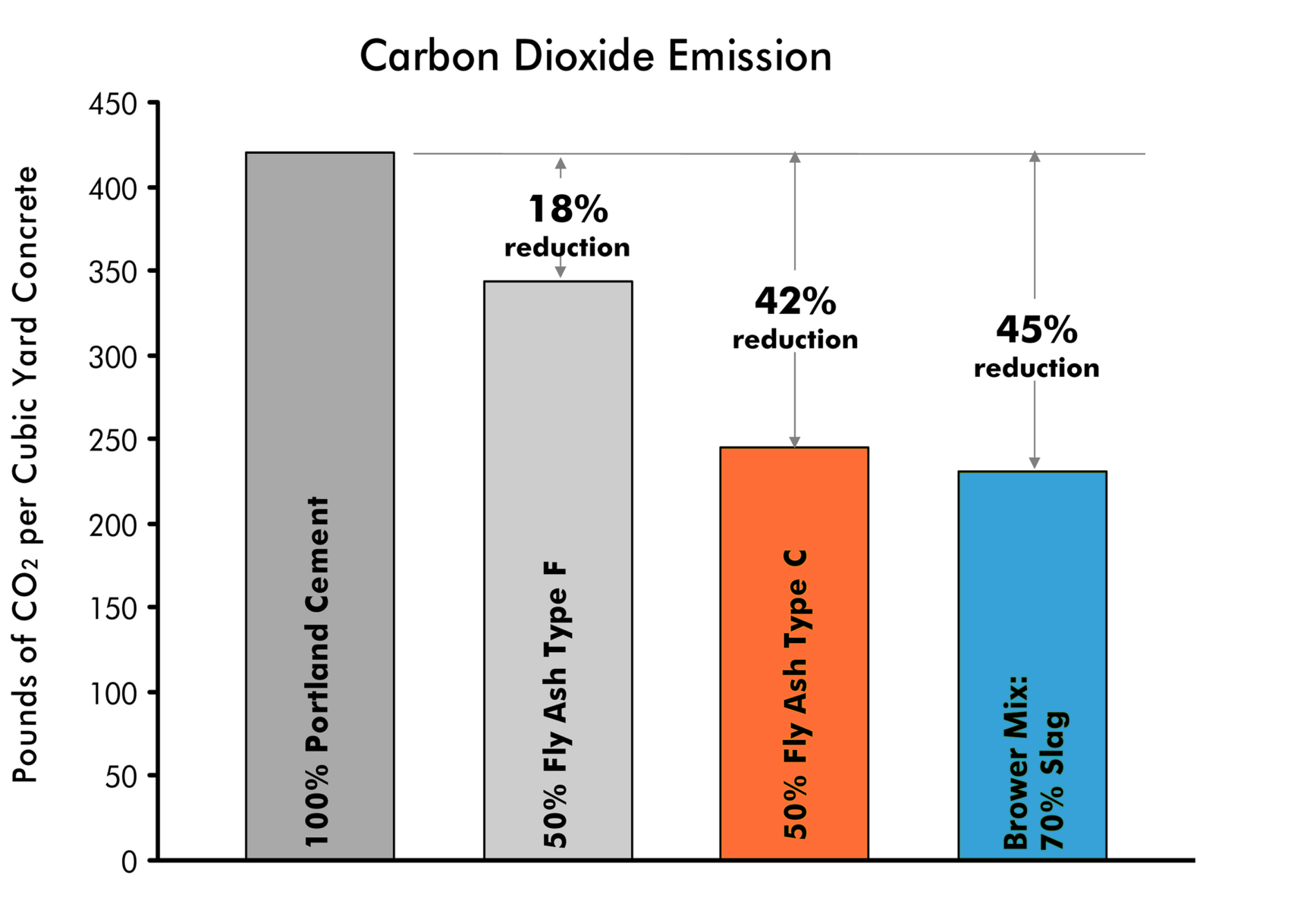

- Decreased the project’s carbon footprint by 7.4 million pounds of CO2 emissions with our specially designed green-concrete mixes. Learn more about green concrete.

- Increased the building’s resilience—and, by extension, the longevity of the investment—by delivering immediate-occupancy post-earthquake performance while saving the project $5 million (or $18/sf) in direct and indirect structural costs, and $27.7 million in downstream costs.

Research and analysis of resource-efficient systems and materials

Tipping has been on the forefront of the use of innovative alternative materials, such as low-cement concrete, mass timber framing, high strength rebar, and resource efficient wood framing. We’ve also led substantial advancements in the use of resource-efficient structural systems, including self-centering shear walls, rocking frames, prefabricated and modular construction, structural insulated panels (SIPs) and tensioned membrane structures.

The David Brower Center in Berkeley, CA is a prime example of how green concrete helped meet sustainability goals. For aesthetic, cost, and environmental reasons, concrete was the material of choice for the structural system. Large portions of the portland cement were replaced with slag (a by-product of steel making) cement. This saved about 5,000 tons of CO2 emissions for the project. Low-impact mixtures were used throughout, with typical portland cement replacement values of 50% for slabs, columns, and walls, and 70% for the mat foundation. This green concrete structural system was a major component in the design team’s ability to create a building that was truly sustainable. Learn more about green concrete.

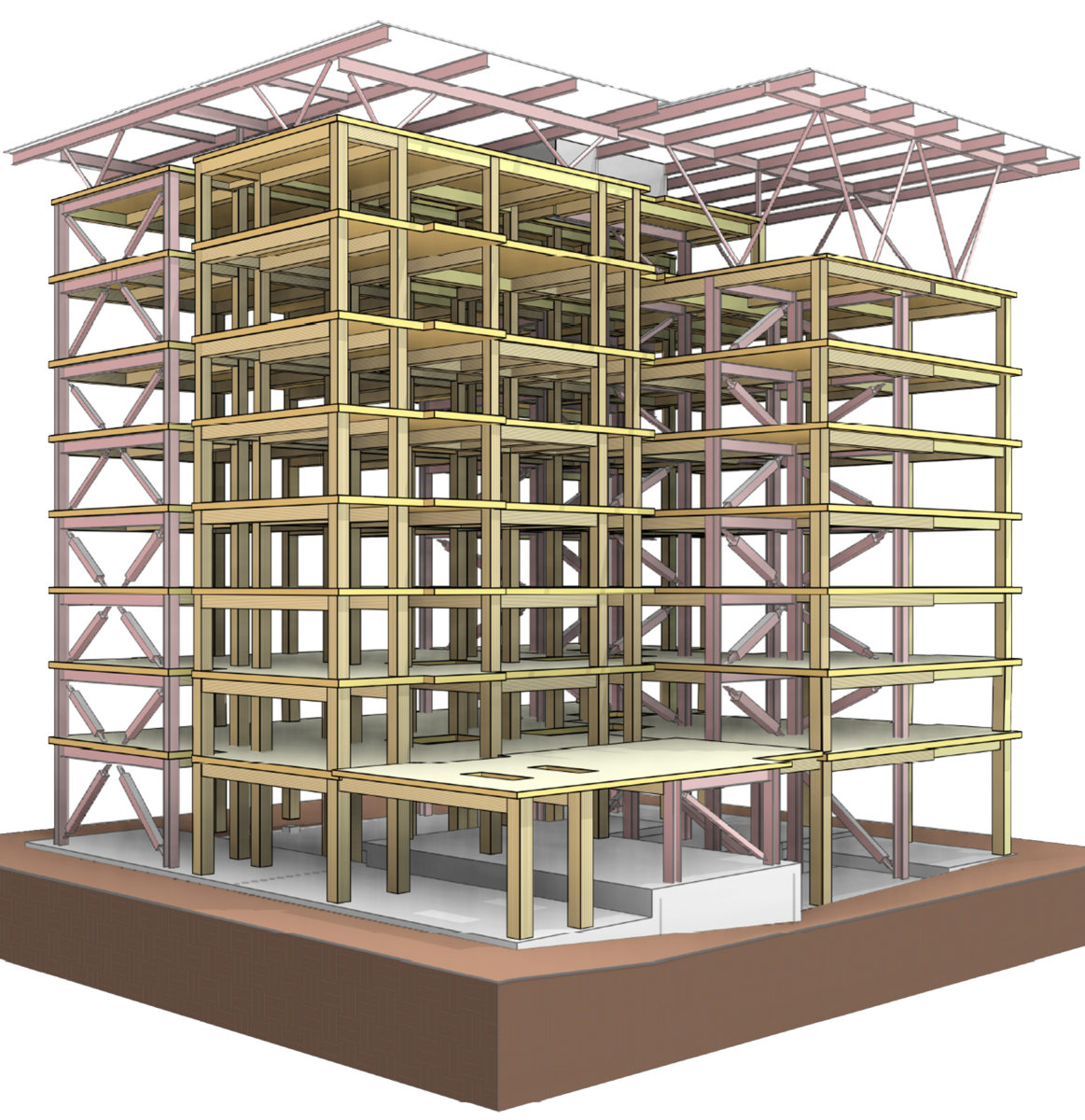

Tipping is currently working on the first Type IV-C to be built in California, a code category that allows for timber structures up to 9-stories and 85 feet tall.

Advancing mass timber’s use in seismically active areas

Mass timber has grown in popularity due to its ability to sequester meaningful amounts of carbon. In fact, wood is the only material that can remove carbon from the atmosphere for the lifetime of its usage. When sustainably sourced, mass timber can be harvested and replenished with fewer lasting environmental impacts than any other known building material. Mass timber products use natural forest resources in a more efficient manner than was historically possible for other types of commercial lumber products, while also helping to reduce the wildfire risk within ecologically managed forests. Tipping is currently deploying our significant seismic experience and analytical tools to identify alternative methods of using mass timber for seismic support of tall wood structures. Learn more about mass timber shear walls.

The Woolsey Gardens project is a pioneering ground-up 8-story mass timber structure that will provide the community with 65 affordable housing units. Designed with both Cross Laminated Timber (CLT) and Glue Laminated Timber (Glulam), an analysis of the design showed a 28% reduction in Global Warming Potential for the timber structure (compared to the same structure built with concrete). In addition to reducing carbon emissions, the Woolsey Gardens project is expected to store nearly 810 tons of carbon over the building’s lifespan—equivalent to the yearly emissions from 102 homes’ energy use. The project is also designed to be LEED-NC Platinum certified and Zero net energy.

Sustainability through retrofit and repurposing

Repurposing existing structures is one of the most sustainable ways we can design. Bringing new life into old structures—through targeted retrofitting, new facades, and building expansions—creates a much smaller carbon footprint than building new. We use advanced analytics to support our innovative approach to retrofits, saving time and money to deliver less intrusive strengthening while further reducing the environmental impacts.

At 633 Folsom, we repurposed the 60-year-old structure with targeted measures, reinventing the existing building to once again inspire its users and contribute to a vibrant community. While demolishing the existing structure and erecting a new building may have been an easier approach, there were many reasons that adapting and expanding the existing reinforced-concrete structure was a wiser decision:

- Repurposing the structure brought inherent sustainable advantages and avoided the excessive waste of demolishing the seven-story structure

- In 1994, Tipping had performed a voluntary seismic upgrade on the building, which provided added strength.

- Vertically expanding the property by five floors offered an opportunity to nearly double its leasable square footage and increase desirability among tenants.

- The project also had the advantage of avoiding a lengthy entitlement and permitting process by gaining approval under San Francisco’s Proposition M and the Office Development Annual Limit Program.