Brower Center

Sustainable design showpiece that met radical goals in sustainability while also boasting a highly effective seismic force-resisting system.

Sustainable Integration

The team’s sustainability goals emphasized efficiency in resource use, reduced embodied energy, and reduced life-cycle cost.

Seismic Resilience

The seismic force-resisting system incorporates post-tensioned, cast-in-place concrete structural walls and post-tensioned moment-resisting frames seamlessly integrated with the architecture.

Situated in Berkeley within 0.6 miles of the Hayward Fault, the David Brower Center is an office building that incorporates many features of sustainable design in its architectural, structural, mechanical, electrical, plumbing, and lighting systems and is LEED Platinum certified.

Meeting ambitious sustainability and seismic goals

The David Brower design team set out to design a building that was truly sustainable—beyond LEED—instead, radically designing a building for damage resistance and structural resilience.

To protect the building against a highly probable major earthquake, the structure integrates an innovative combination of post-tensioned concrete walls and frames that will improve performance and limit damage. The system’s defining feature is its unique, recentering behavior that virtually eliminates permanent post-earthquake deformations. It combines the elasticity of high-strength, unbonded tendons with the energy-dissipation capacity of mild steel reinforcement to control the structure’s inelastic response—a significant enhancement over yielding systems that can suffer permanent drift.

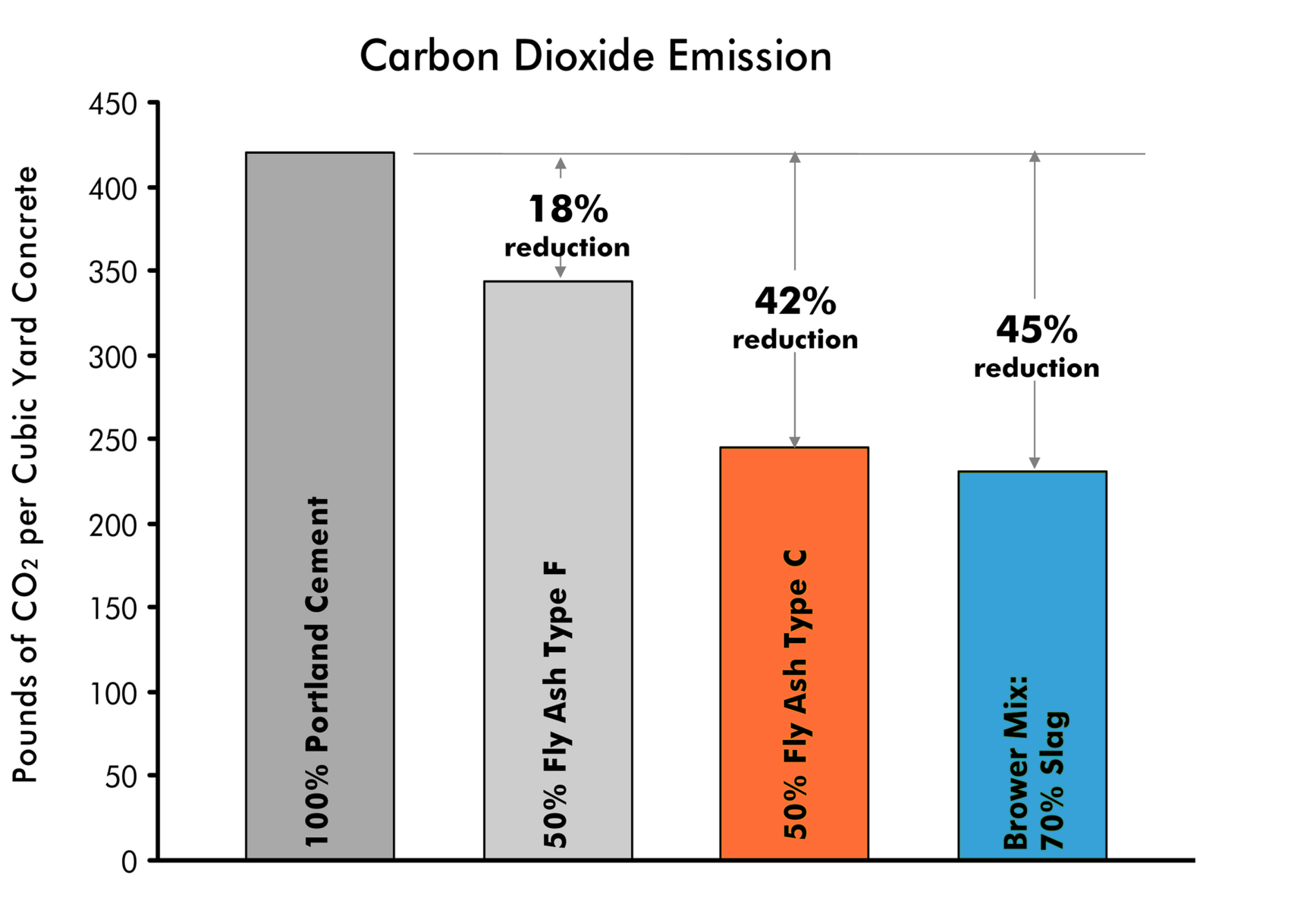

Additionally, cement mixtures utilized large volumes of slag cement instead of Portland cement to dramatically reduce the embodied energy and carbon footprint of the structure—up to 45 percent of CO2 over standard concrete, even after considering the impact of transporting the slag from China and the aggregate from Vancouver.

Executed as Tipping Mar

-

Location

Berkeley, CA

-

Square Footage

44,000 sf

-

Cost

$22 million

-

Completion Date

2009

-

Owner

David Brower Center

-

Architect

Mithun (as Solomon E.T.C.)

-

Contractor

Cahill Contractors

-

Developer

David Brower Center / Equity Community Builders

-

Photography

Tipping

AWARDS

SEAONC | SEOC 2010 Awards of Excellence in Structural Engineering

AIA COTE Top Ten Green Project 2009

LEED Platinum certified

Post-tensioned concrete seismic system

To best meet the cost and environmental goals for the project, the seismic force-resisting system incorporated post-tensioned, cast-in-place concrete structural walls and post-tensioned moment-resisting frames that are seamlessly integrated with the architecture. The flexural behavior of a post-tensioned structural system is ideal for this application. The mild steel reinforcing bars yield to dissipate energy during a seismic event, while the unbonded tendons remain elastic to provide a positive restoring force that recenters the structure afterwards. The elastic restoring component is proportioned to be somewhat larger than the yielding component: slightly more than half the total resistance is derived from post-tensioning and contributes to the recentering effect.

A variety of sustainability elements, including a low-impact concrete mixture, contributed to a LEED Platinum certification from the USGBC. (Graphic courtesy of WRT/Solomon E.T.C. / now Mithun)

Concrete and carbon footprint

For aesthetic, cost, and environmental reasons, concrete was the material of choice for the structural system. Thermal mass is a key factor in reducing operational energy usage, and the slabs were integral to the radiant heating and cooling systems. The mechanical distribution is a raised-floor system, allowing the slab soffits to remain exposed as a finished ceiling and the hydronic tubes to be located at the bottom of the slabs, simplifying installation. Cost and seismic mass were saved by eliminating the traditional topping slab. The Brower Center’s concrete frame embodies the principles of integrated design: it is the structural system, a key component of the mechanical system, and the dominant feature of the architectural expression.

Minimizing the portland cement used in the concrete was a key factor in attaining the project’s sustainability goals. Large portions of the portland cement were replaced with slag (a by-product of steel making) cement. This saved about 5,000 tons of CO2 emissions for the project. Low-impact mixtures were used throughout, with typical portland cement replacement values of 50 percent for slabs, columns, and walls, and 70 percent for the mat foundation. This “Green Concrete” mixture was first developed under a grant from the Kresge Foundation, and then refined in collaboration with the concrete supplier for the Brower Center.

A variety of sustainability elements, including a low-impact concrete mixture, contributed to a LEED Platinum certification from the USGBC. (Graphic courtesy of WRT/Solomon E.T.C. / now Mithun)