Intuit Dome Trellis

A rare opportunity where structural design actively shapes the design of a long-span, tensile lightweight structure in a prominent urban plaza.

Advanced Analytics

A wind tunnel study yielded 80 unique load combinations, integrating wind forces and fabric pretension reactions to determine member sizes and meet deflection limits.

Innovative Design

The element layout and sizes were directly informed by the structural demands, informing the shape of the tapered columns, profile of the trusses, and dimensions of the tension and compression members.

Integrated Value

Simplifying the installation process within an active jobsite, the truss structure was designed with 300 bolted connections which allowed the entire structure to be erected efficiently with minimal field welding.

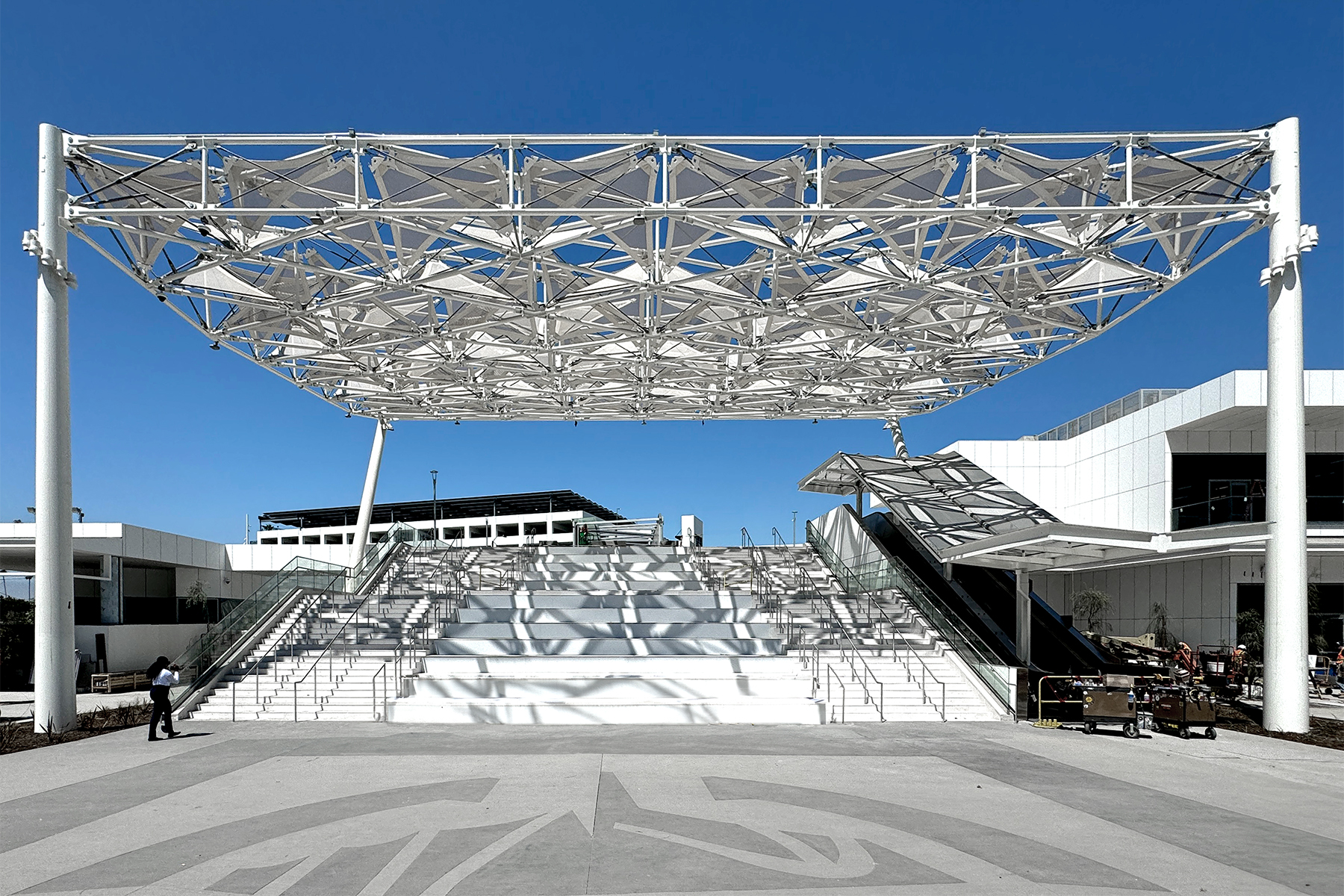

The Intuit Dome, the new home of the Clipper’s in Inglewood California, represents a collaboration among multiple design partners to create a welcoming urban event space. The entry plaza serves as the main promenade to the arena, as well as a vibrant community gathering space featuring an outdoor basketball court, an amphitheater, and tiered seating. A defining architectural element of the entry plaza is the lightweight, long-span steel trellis with tensile fabric panels, which defines an important gateway to the plaza and arena.

Structure as “Sculpture”

Working closely with Hood Design Studio, the urban and trellis designer, the team aimed to create an inviting and human-centered space within the urban environment. Walter Hood’s philosophy, emphasizing the creation of spaces for people, drove the design of this plaza space with much needed shade in the Southern California climate. The team sought to highlight the structural design of the trellis: The result is a celebration of the optimum structural design for a long-span tensile shade trellis.

-

Location

Inglewood, CA

-

Square Footage

6,700 sf

-

Cost

Confidential

-

Completion Date

2024

-

Owner

Los Angeles Clippers

-

Architect

Hood Design Studio (Trellis Designer)

-

Contractor

AECOM, Hunt

-

Photography

©Brian Feinzeimer, ©City Design Studio, ©Michael Juliano for Time Out, ©Tipping

The trellis—a two-way truss system with bolted connections, tension rods, and pretensioned shade panels—is a gateway to the active public plaza and Intuit Dome arena.

Efficient and dynamic design

The trellis spans 93 feet by 73 feet and soars to a height of 50 feet above ground. This expansive, permeable structure appears to float effortlessly above four dramatically tapered and sloped cantilever columns. Framed by four primary perimeter trusses, the interior framing features a two-way truss system oriented at a 40 degree offset as a nod to the geometric and dynamic façade of the adjacent Arena. The density of structural members and size of the fabric panels were key drivers in the shade structure’s design.

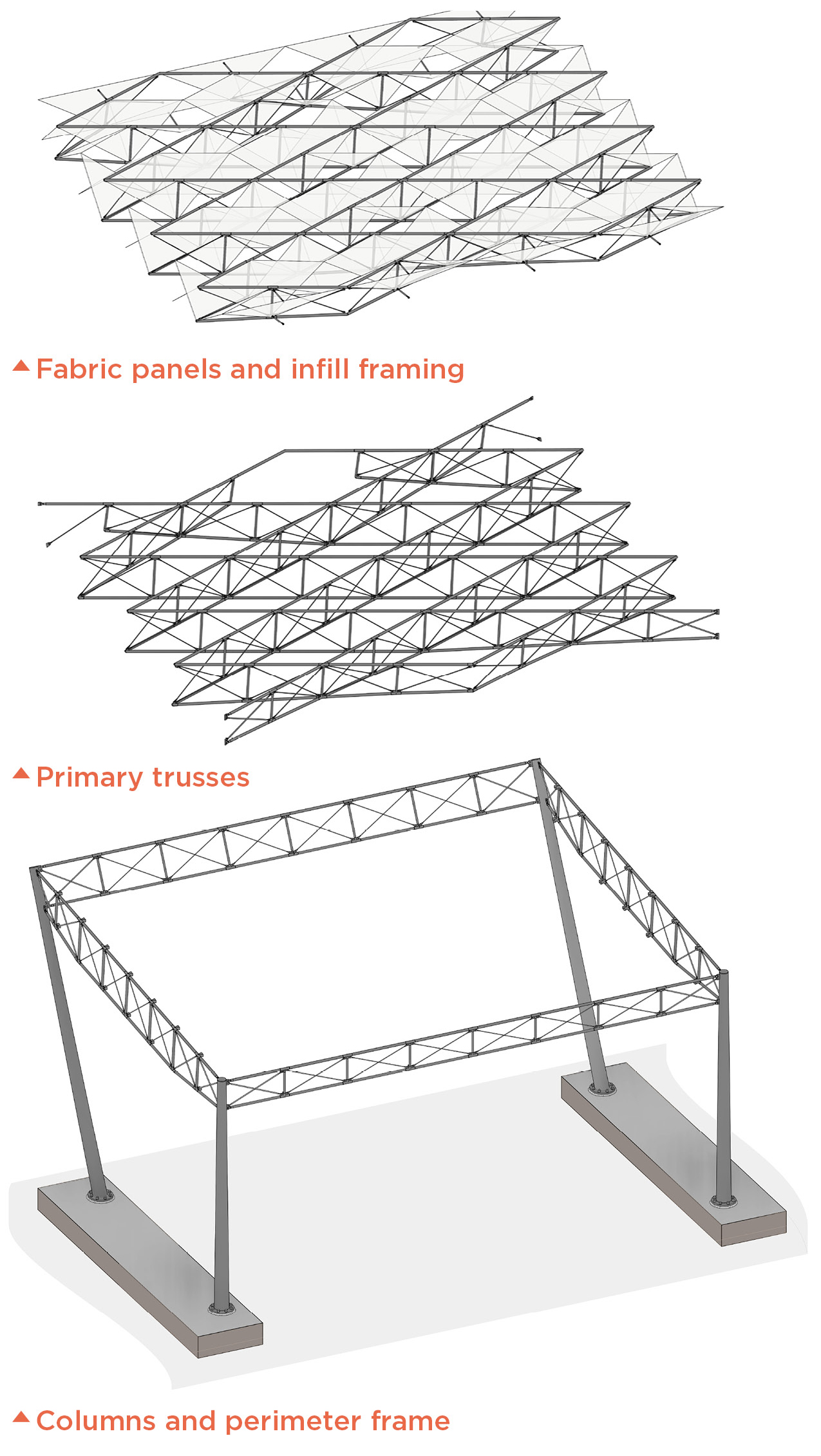

Fabric panels and infill framing The density of structural members and size of the fabric panels were key drivers in the design. The profile of the trusses vary in depth, becoming shallower at the exterior edges to optimize member sizes and load distribution.

Primary trusses Two-way truss system is offset at a 40 degree mimicking the Arena’s geometric façade. Every other bay of framing is load-bearing, to optimize efficiency.

Columns and perimeter frame Rising 50 feet above ground, the trellis structure spans 93 feet by 73 feet. The canopy is gracefully supported by four tapered, sloped, and cantilever columns, anchored to shallow footings. The four cantilever columns support all lateral loads with rigid bolted connections to grade-beam foundations. The truss connections to the columns were carefully analyzed and detailed to minimize stress concentrations and ensure reliable seismic response.

Performance-based design

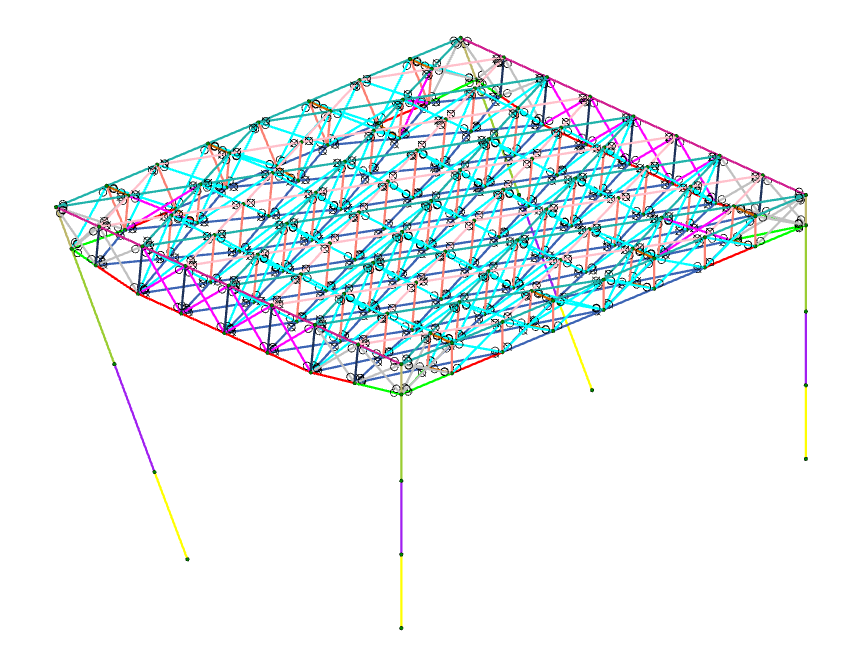

Owing to the structure’s complex geometry, a wind tunnel study was conducted to establish reliable load estimations. The studies provided 14 different wind load cases with varying magnitudes, which were then used for the design of both the truss structure and fabric panels. The design loads also included the pretension reactions of the tension fabric, which fluctuated based on the wind load intensity. The combined effect of these factors resulted in 80 load combinations, which were used to determine member sizes and meet deflection limits.

Constructability

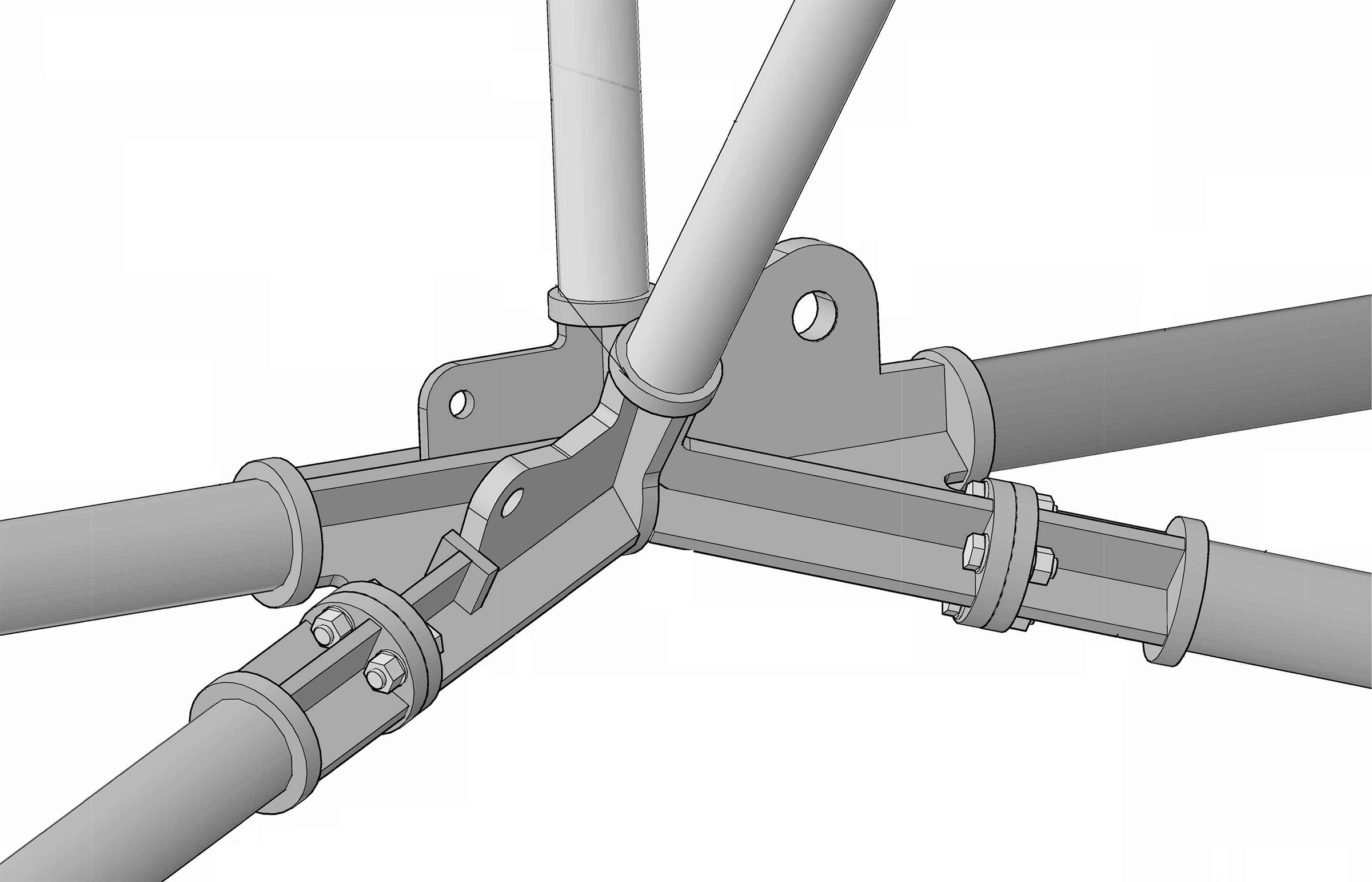

The large trellis structure was designed with ease of constructability in mind. Due to the construction of other elements on the site, the installation of the structure needed to be simplified and easily assembled on site.

To achieve an efficient assembly, the truss structure was designed with 300 bolted connections. This approach enabled the entire structure to be shipped on standard trailers, lifted into place, and erected with minimal field welding. The design leveraged the use of clevis pin connections for the diagonal truss members to provide adequate tolerance and simplified assembly.