West Berkeley Medical Office Building

An innovative structural system brings needed medical services with creative architecture to a West Berkeley neighborhood.

Seismic Resilience

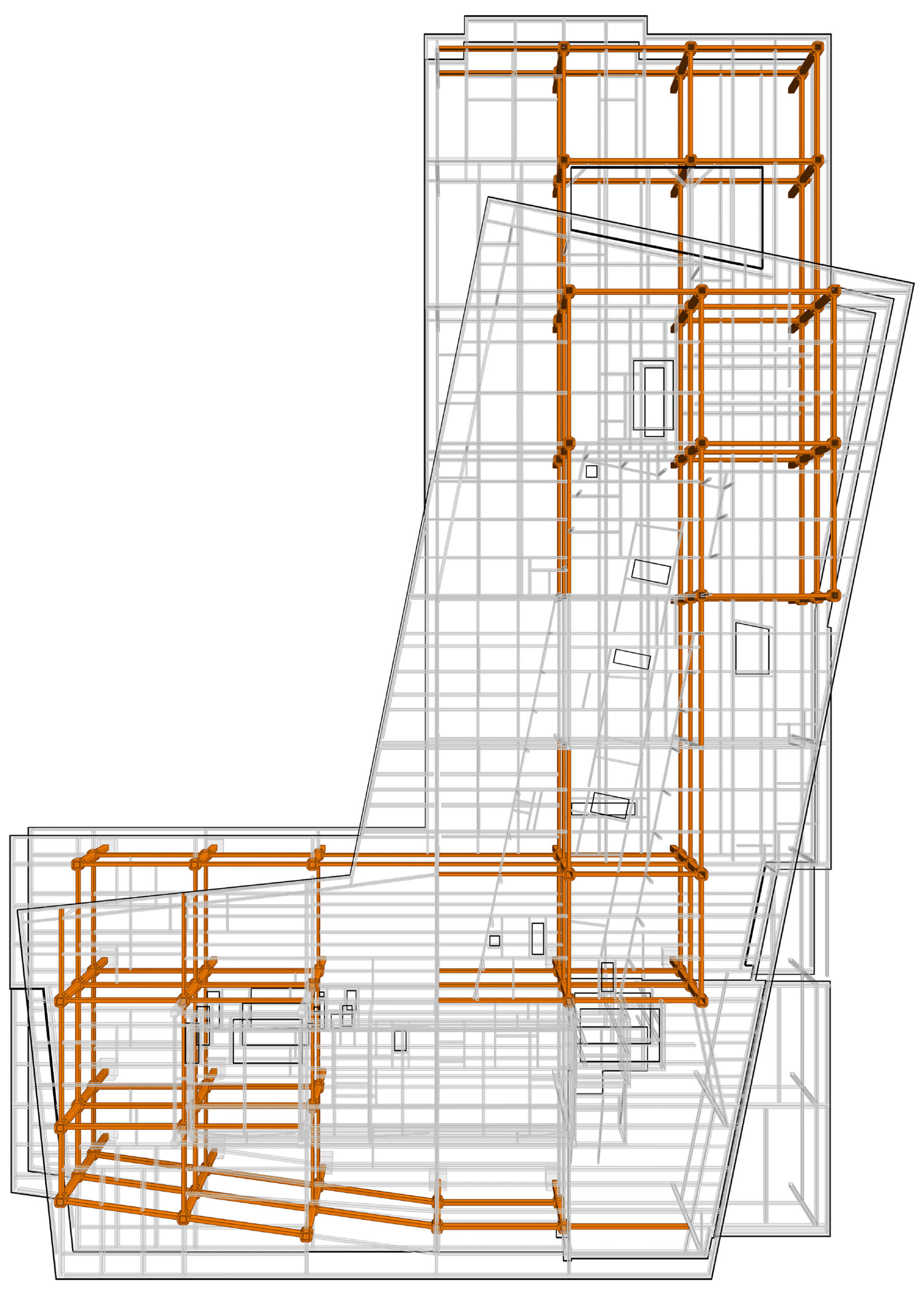

Sufficient moment frames were provided to prevent excessive torsion and improve the structure’s overall seismic performance.

Innovative Design

The design team chose ConXtech moment connections for the lateral system, integrating with the unique architecture, tuck-under parking, and flexibility of future tenant needs.

Integrated Value

The chosen structural system resulted in expedited construction installation time and construction schedule reduction. The primary steel frame was installed in about half the time of a conventional steel braced frame structure.

Sited on an approximately 1.58 acre infill site in West Berkeley, this medical office building accommodates two full stories and a partial ground floor, essentially unenclosed and integrated into the parking lot occupying the rest of the site. Tenanted by Kaiser Permanente, it offers adult family medicine services, pediatrics, mental health care, a pharmacy, and other outpatient offerings, as well as a café, providing critical medical services to the local community.

Challenges

Laboratory and medical office structures are typically steel-framed and often use steel braced frames for seismic lateral resistance. For this project, steel braced frames were deemed impractical: at the ground floor, the brace locations would impact parking and drive aisles, while at the upper levels, the skewed and twisting floor plan did not allow for the brace frames to stack vertically. A concrete structure with concrete shear walls was also considered but ruled out due to the shear wall’s impact on the ground floor parking and the lack of flexibility for future tenant revisions. As an additional complexity, there was no specific tenant on board during the project’s design phase. Thus, the building was designed on specification for future medical office or light laboratory use. Designing a future medical office building is challenging because these buildings have heavy mechanical and equipment demands that frequently add significant loading to the structural framing, not to mention tenant-specific MEP systems and floor plate requirements.

A unique design for a unique site

The L-shaped 66,000-square-foot structure embraces the challenging small infill site with an integrated design that allows for open floor plates and a stunning architectural design. The design team determined that the structure would be steel-framed and use the ConXtech moment connections for the lateral system, integrating with the unique architecture, tuck-under parking, and allowing for flexibility with future tenant needs. The property was sold to Kaiser Permanente after the design was fully permitted, putting the design flexibility of the steel-framed structure to the test. Fortunately, the design team found that with careful planning and by leveraging past experiences, the primary structure was designed to accommodate much of the new tenant’s needs without significant structural revisions.

-

Location

Berkeley, CA

-

Square Footage

68,000 sf

-

Cost

$20 million

-

Completion Date

2021

-

Owner

Wareham Development

-

Architect

Gould Evans

-

Contractor

XL Construction

-

Photography

Cris Gebhardt

AWARDS

LEED Gold Certified

ConXtech collar

Advantages of the ConXtech system

The ConXtech steel moment frame system features a proprietary interlocking beam-column connector, the moment frame columns are concrete-filled HSS shapes, and the beams are wide flanges with reduced beam sections (RBS). Fully restrained beam connections are achieved through the ConX collar assemblies. Nesting components of the collar are robotically shop welded to the beams and columns. Then, the beams are simply lowered and locked into position at the construction site, and pre-tensioned high-strength bolts are installed. The limited field welding with this system results in substantial time savings in the construction schedule.

ConXtech bi-axial bolted moment frame connection

Expedited construction installation time

The primary steel frame was installed in approximately a week and a half, equating to about half the time of a conventional steel braced frame structure. The ConXtech system primarily relies upon a field-bolted system for gravity and moment frame connections to expedite the steel erection and field labor. ConXtech leverages a BIM Tekla model and a fully robotic fabrication system to ensure the necessary precision for the field-bolted system. The design team collaborated closely with ConXtech during the design and construction phases, including sharing Revit models to confirm dimensions and steel framing details.

A structural system that seamlessly integrates with architecture

The building site consists of up to three feet of compressible fill with some potential for liquefaction settlement and moderate expansion potential; these soil conditions played a major role in determining the chosen structural system. The geotechnical recommendations allowed for the use of shallow spread footings with an allowable bearing pressure of 3,500 psf; however, the design team targeted an allowable gravity bearing pressure of approximately 1,600 psf to reduce the overall differential settlement. Combining the distributed ConXtech moment frame system and the lighter steel-framed structure allowed for the cost-effective use of conventional spread footings. A concrete structure at this site would have incurred additional costs for either soil improvements or a pile foundation system due to the heavier structure.

Additionally, the ConXtech system allows for moment frame beams to skew in plan up to 15 degrees, facilitating the architectural expression along the west slab edge with minimal impacts to the lateral system design.

ConXtech moment frame lateral system highlighted in orange

Seismic resilience

Limiting the building’s torsion during a seismic event was another significant design consideration. Since the building is located in Seismic Design Category E, having an Extreme Torsional Irregularity is not permitted. Additionally, a design decision was made to limit building torsion below the threshold for Torsional Irregularity to improve the structure’s overall seismic performance. Consideration of torsion also factored into the redundancy check. Because of the re-entrant corner, the structure is classified as an irregular structure. Sufficient moment frames were provided to prevent excessive torsion and improve the structure’s overall seismic performance to keep the redundancy factor at 1.0. The analysis showed that the seismic drift was reasonably uniform and less than two percent at the corners because of the distributed lateral system.