San Francisco Public Utilities Commission Headquarters

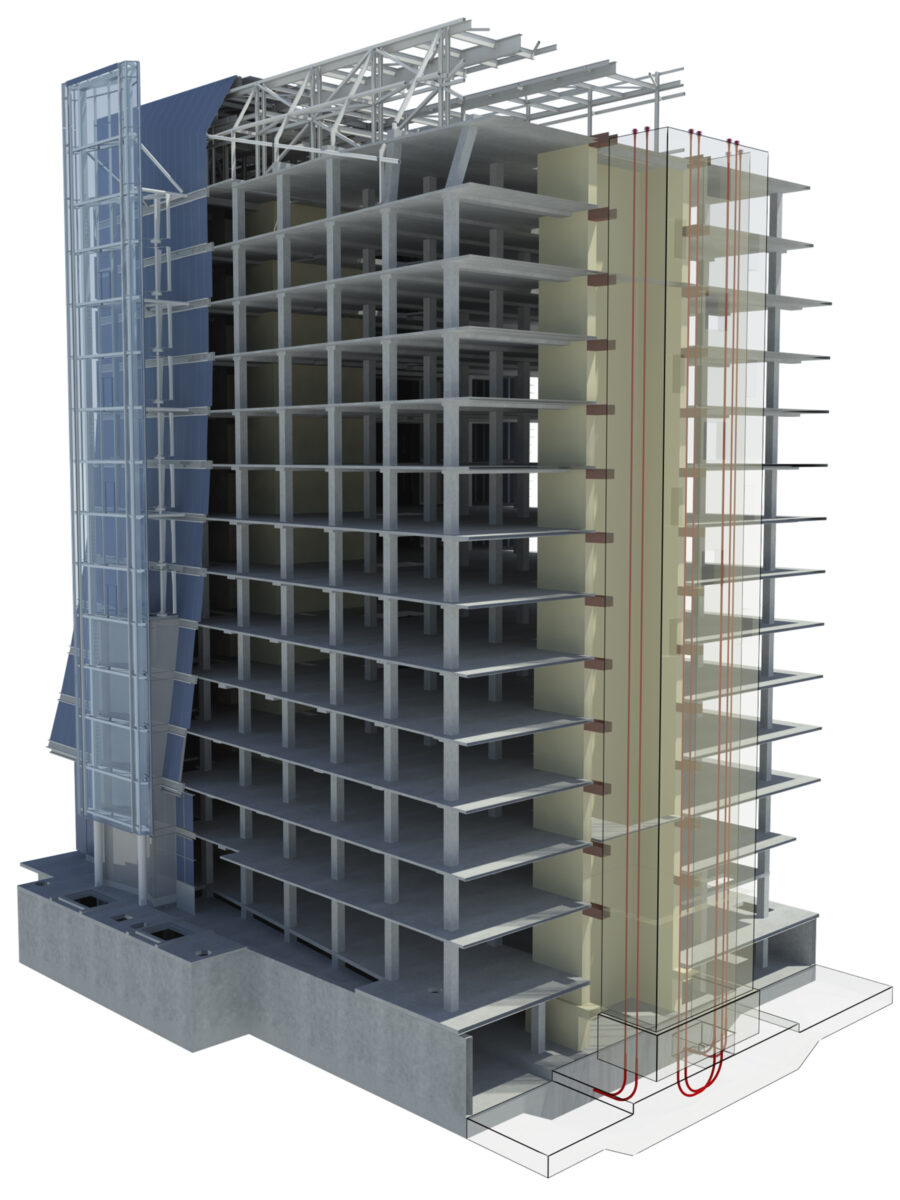

An innovative structural system adapted from bridge engineering saved the project $30 million while also achieving LEED Platinum certification.

Integrated Value

Completely redesigned during the construction documentation phase, Tipping’s post-tensioned concrete core structural system saved the project $30 million in direct, indirect, and downstream costs.

Sustainable Integration

One of the greenest office buildings in North America and LEED Platinum certified, the SFPUC boasts wind turbines, solar panels, and a Living Machine that renders black and gray water reusable.

Seismic Resilience

Self-centering system eliminates post-earthquake deformations and re-centers the structure. Elevated performance goals ensure ability to allow for immediate reoccupancy and rapid functional recovery.

Innovative Design

Post-tensioned concrete cores with composite link beams provide a highly efficient and cost-effective structural alternative to more exotic and expensive approaches.

The lateral system of the SFPUC headquarters was originally designed in 2000 as a twelve-story base-isolated building that would be immediately reoccupiable after a large earthquake. The project went on hold in 2002 in the wake of the dot-com crash. When it was resuscitated four years later, the original scheme gave way to a steel-framed structure with viscous dampers. That design, too, proved financially infeasible in the context of the 2007 financial crisis. In 2008—well into the construction documentation phase—Webcor Builders asked Tipping to redesign the SFPUC building in concrete while fulfilling the mandate of immediate reoccupancy level performance.

An unconventional solution

Our design solution for the SFPUC HQ cost-efficiently meets the standard of Immediate Occupancy under the Design Basis Earthquake hazard while delivering increased constructability and shortened construction time, and saving the project almost $30 million in direct, indirect, and downstream costs; and reducing the carbon footprint by fifty percent.

We utilized a recent innovation from our team—a hybrid lateral system involving vertically post-tensioned concrete cores—which was adapted from bridge engineering and designed to return a structure to plumb after a significant earthquake. In redesigning the SFPUC headquarters in concrete, Tipping implemented the latest iteration in a series of “self-centering” walls, meeting the performance mandate and budget.

A long-awaited green update

After twelve years of planning, design, redesign, and finally construction, the San Francisco Public Utilities Commission’s new headquarters at 525 Golden Gate Avenue opened in June 2012. Designed to achieve LEED Platinum certification by KMD Architects with Stevens and Associates Architects, the 277,500 sq. ft. structure is said to be one of the greenest office buildings in North America, complete with wind turbines, solar panels, and a Living Machine that renders black and gray water reusable.

-

Location

San Francisco, CA

-

Square Footage

277,500 sf

-

Cost

$14.5 million

-

Completion Date

2012

-

Owner

City of San Francisco/ Department of Public Works

-

Architect

KMD Architects with Stevens and Associates Architects

-

Contractor

Webcor Builders

-

Photography

Bruce Damonte

AWARDS

2013 NCSEA Excellence in Structural Engineering, Outstanding Project Award, $100 million-plus category

2013 SEAOC Excellence in Structural Engineering Award, Sustainable Category

2013 SEAONC Excellence in Structural Engineering Merit Award, Sustainable Category

LEED Platinum certified

An Innovative and robust seismic frame is a key part of a San Francisco office building's sustainable strategy and its bid for LEED Platinum.

- "Green at Its Core", by Joann Gonchar, AIA, Architectural Record, June 2011

A design solution that adds value

Our design solution:

- Moved from a heavy steel moment frame to thin PT concrete slabs: the reduction in floor-to-floorheights accrued to allow an additional story within the same building envelope and with improved ceiling aesthetics, leading to not only greater usable real estate, but also to higher density—an important sustainability goal;

- decreased the project’s carbon footprint by 50% (7.4 million pounds of CO2 emissions) from an embodied energy standpoint, in comparison to conventional concrete mixes;

- saved the project $4 million in direct structural costs, $1 million in indirect structural costs, and $24.7 million in downstream costs ($11 million on skin, $10 million on the mechanical system, and $3.7 million on the electrical system), a total saving of almost $30 million, as described in “Tensioning Eases Stress,” the feature article in Engineering News Record’s February 20, 2012 issue.

Structural solution: post-tensioned concrete cores

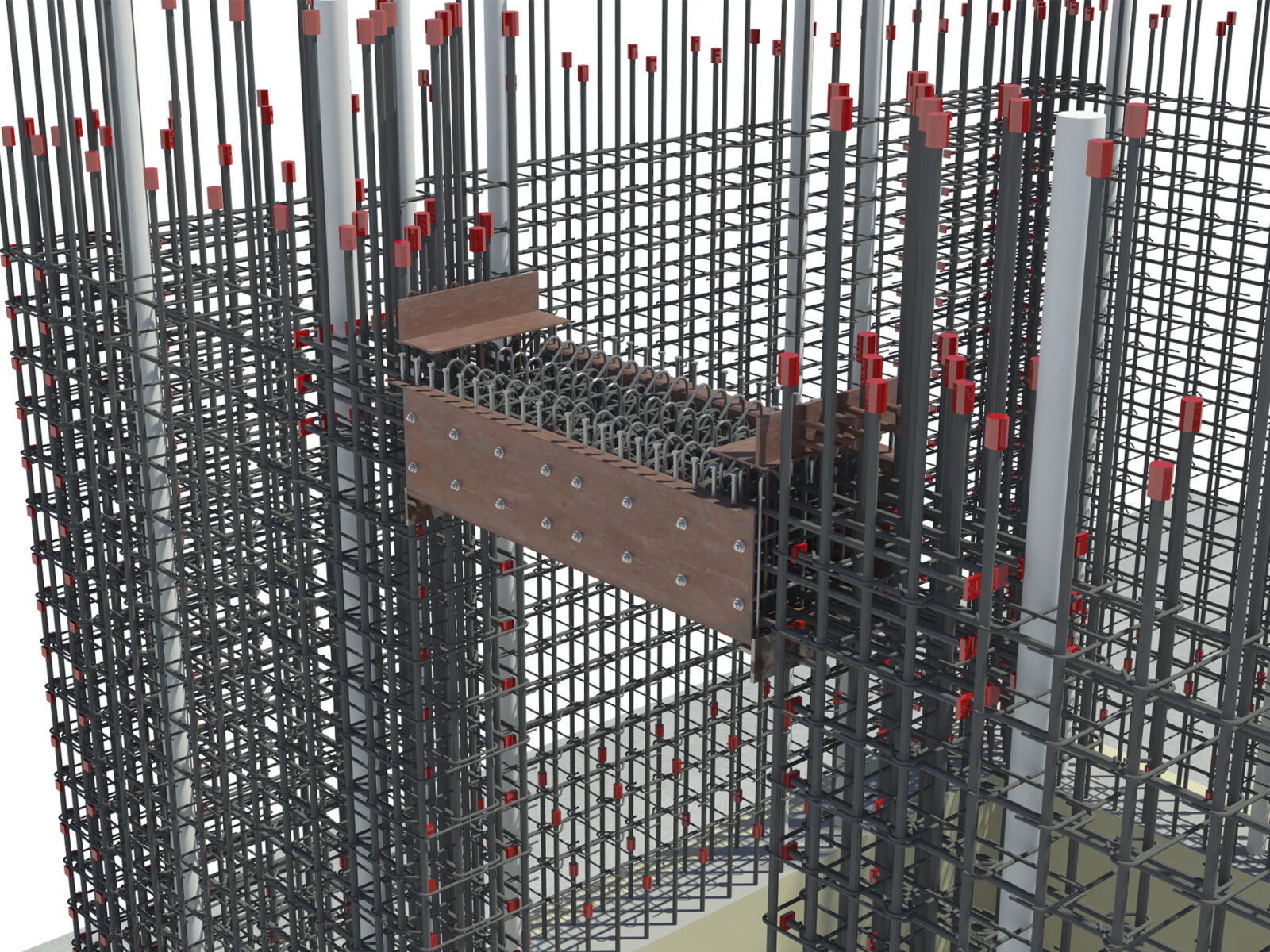

The lateral system comprises two concrete cores—approximately 30-foot-square in plan and rising the height of the building—supported by a concrete mat foundation and micropiles. Tipping designed an innovative link-beam system, consisting of a steel jacket and conventional steel reinforcement, to simplify construction and improve seismic performance. Learn more about post-tensioned walls.

Each vertically post-tensioned core incorporates eight bundles of tendons; in turn, each bundle comprises 28 strands, each measuring 0.6″ in diameter. Each bundle was fed through a U-shaped steel duct 375 feet long, and anchored at the roof with one million pounds of permanent force. The tendons act like giant elastic bands, allowing the building to first yield and then return to plumb after a large seismic event. The strength of the cores was tuned to limit drifts so that the expensive skin system would remain damage-free during a Maximum Considered Earthquake event.

Model of optimized link-beam showing steel jacket

Special green concrete mixes

Tipping initiated design charettes with Central Concrete to arrive at several low-cement concrete mixes for the project that neither added cost nor compromised the construction schedule or constructibility. In these mixes, 40 to 70 percent of the Portland cement was replaced with slag and fly ash. Moreover, the light color of slag complemented the project’s daylighting strategies.

Learn more about green concrete.