UCSF Mount Zion Housing

An exoskeleton retrofit approach offers efficiencies, performance, and architectural enhancement.

Advanced Analytics

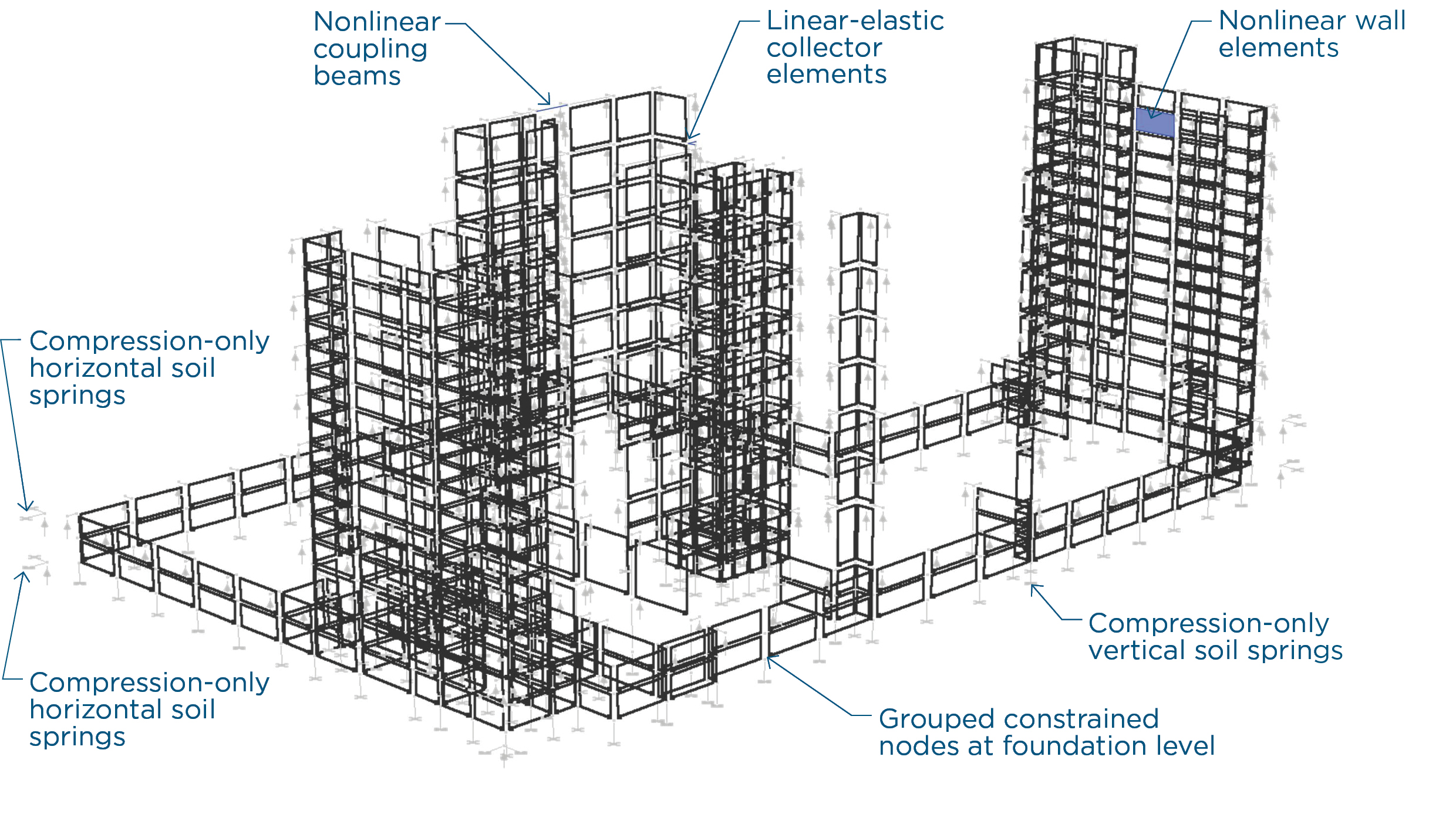

A detailed nonlinear analysis allowed us to devise an exoskeleton approach that strengthened the building's existing structure while limiting the need for interior alterations and the subsequent costly repair of finishes.

Integrated Value

Our targeted retrofit design was estimated at $4.2M, reducing the estimated retrofit cost by roughly 75% and leaving remaining funds available for other building upgrades.

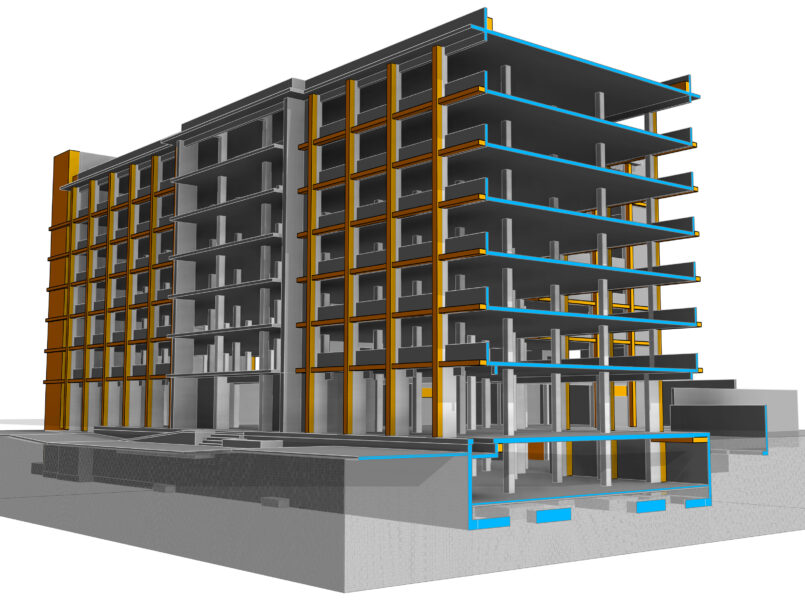

Mount Zion is University of California, San Francisco’s newest facility providing faculty with below market rate housing. Constructed in 1968, the seven-story concrete building was generously gifted to the University to help lure talented faculty. While the building had undergone significant interior renovations in 2012, the structure did not meet the University of California’s rigorous seismic standards.

Challenges

Prior to engaging Tipping, a previous retrofit scheme commissioned by the University required the removal and replacement of all windows to allow exterior captured columns to be wrapped with Fiber Reinforced Polymer (FRP) for shear strengthening. This scheme was estimated at $17 million, far above the University’s budget for the project. The new project team was charged with finding a more cost-efficient approach to strengthening this new University asset.

A targeted retrofit

The University commissioned the project team to lead an innovative, cost-efficient retrofit to protect the building and inhabitants. Through a data-driven process, we uncovered a series of surgical seismic interventions that strengthened the building without requiring excessive demolition. Interior columns were wrapped with FRP for added strength, using a three sided-wrap that was designed, tested and approved to further avoid unnecessary and expensive interior demolition. Through close collaboration with the architect, the exoskeleton design was detailed to enhance the aesthetics of the existing, nondescript 1968 façade, while also providing energy performance improvements through increased shading.The newly articulated main façade brings the aging facility into the 21st century, while providing enhanced seismic performance to the owner and the building’s new residents.

At the center of the solution, an unconventional exoskeleton approach met the University’s strict seismic demands while also adding an updated aesthetic to the aging building’s main facade.

-

Location

San Francisco, CA

-

Square Footage

120,000 sf

-

Cost

$20 million

-

Completion Date

2021

-

Owner

UCSF Real Estate Services

-

Architect

Gelfand Partners Architects

-

Contractor

Webcor Builders

-

Photography

Webcor staff; Tipping staff; Gelfand staff

AWARDS

2024 NCSEA Structural Engineering Excellence, Outstanding Structure

2023 SEAONC Excellence in Structural Engineering, Award of Merit, Retrofit

The relatively flat facade of the 1968 non-ductile concrete structure features spandrel beams, creating a captured column configuration susceptible to shear failure

The new exoskeleton is designed to fit in with the architecture of the existing facade protecting vulnerable gravity columns

The creative use of the exoskeleton was a very effective way to strengthen the building with minimal cost and impact to the building.

- SEAONC Jury, Award of Merit, Retrofit/Alteration

Sophisticated shaking simulations using nonlinear structural models to validate performance and optimize the design

Advanced analytics

A comprehensive nonlinear model of the existing structure with proposed retrofits was built and reviewed and approved by the UC San Francisco Seismic Review Committee. The data-driven process allowed the team to harness the inherent strength of the structure and target localized strengthening using an exoskeleton that minimized demolition within the building. Once the retrofit scheme was developed and priced during design, it was estimated at $4.2 million, far below the University’s budget; the budget surplus allowed for other ADA and mechanical upgrades to be included in the project. The work brought it into compliance with UC Seismic Safety Policy requirements meeting or exceeding performance level IV.

Learn more about advanced analytics.

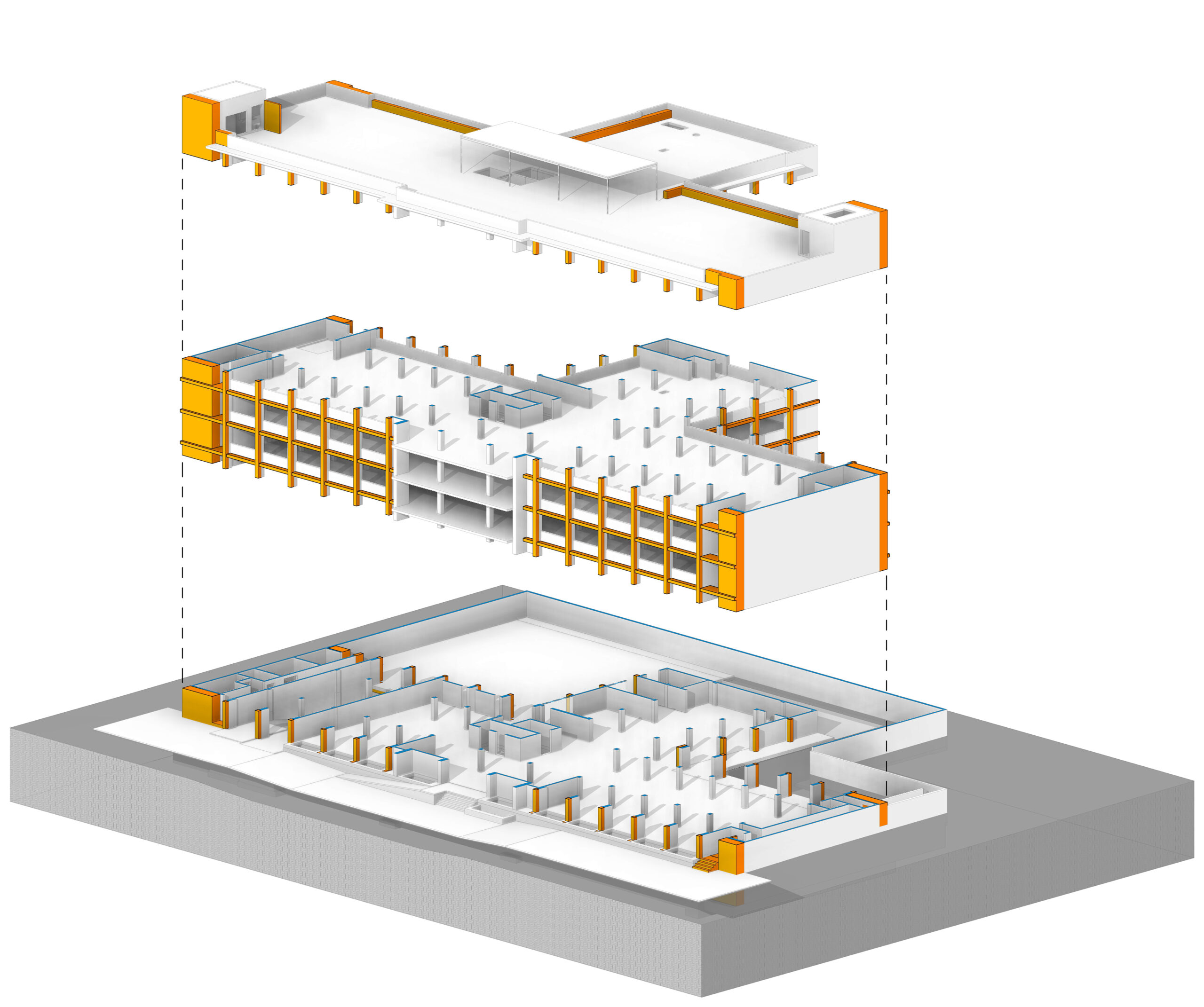

Exploded view of exoskeleton, new shear walls, and collectors

Exoskeleton

New exterior concrete columns designed as “back-up” gravity supports were added to provide an alternate load path around the existing exterior captured columns, which were expected to fail in shear under intense shaking. The extension of existing slabs at each floor serve to (1) provide a gravity load path to the new exterior columns, and (2) as collectors transferring diaphragm forces to four new flexural shear walls at the east and west wings. The shear walls reduce drift and improve the building’s overall deformation profile. Large seismic shear and overturning forces are distributed to the building’s existing basement walls through a series of distributor beams and wall extensions at the basement level.

Three-sided column wrap testing at Simpson Strong-Tie

Column fiber reinforced polymer wrap

The interior columns are wrapped with FRP for added strength. At some locations, columns could not be fully wrapped because the fourth side was not accessible or would require expensive demolition and refinishing. A three-sided solution was designed using FRP through-anchors, in lieu of the fourth side of wrapping. The testing proved the three-sided wrapping approach would avoid a shear failure of the column, allowing it to accommodate the expected drifts of the target hazard.

Learn more about Composite-fiber column retrofits.

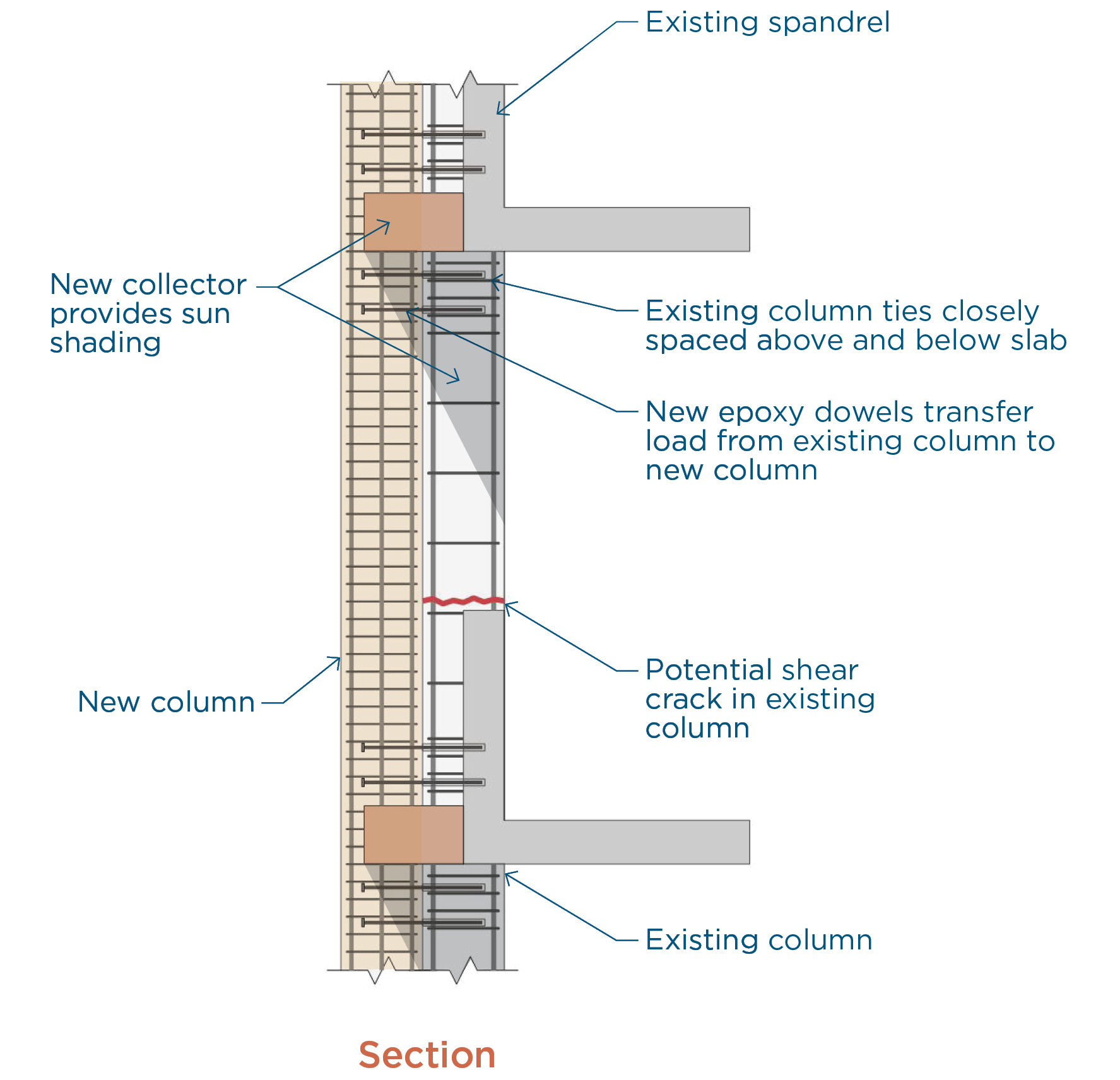

Typical retrofitted exterior bay with slab extensions serving as gravity support beams, collector elements, and sunshades

Architectural benefits

The exoskeleton approach also contributed to the architectural aesthetic of the structure’s 1968 facade. Working closely with the architect, the connections between the columns and slab extensions were detailed to enhance the existing, relatively flat facade. The exoskeleton system also added 10 inches of depth to the overhang above each large window, providing much needed shading during the summer months when heat gain and glare are a concern of users, particularly on the south facade.

Frame of new exoskeleton in front of old columns, tied with epoxy dowels

Facade with new exoskeleton